Algae!!!…Green, gooey, slimy, messy, smelly, unpleasant…All these words come to mind when I hear the word “Algae”.

What if I told you algae has the power to revolutionize the world today. Oh yes! There is an “Algae Revolution” and it is quite fascinating.

Just imagine yourself, walking into a coffee shop with your own bag of kelp (an algae) and leaving with your hot coffee in a kelp-cup made onsite. Get ready to be blown away…

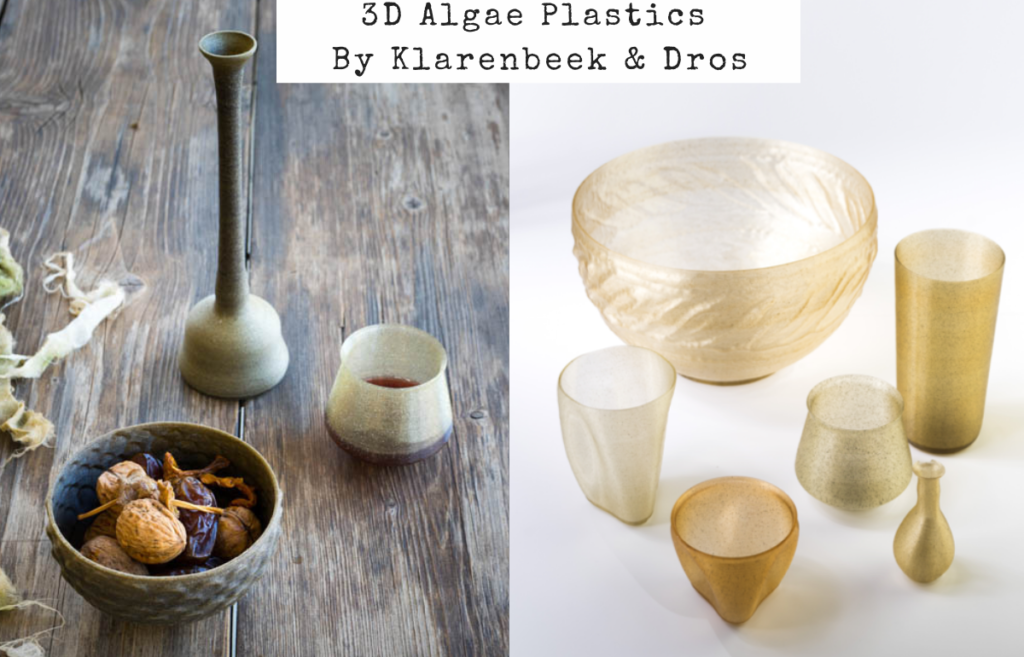

From Algae to Plastics

In 2011, after visiting a recycling station in Mumbai, Eric Klarenbeek started investigating the potential to 3-D print objects from unusual materials. He started with mycelium (a glue-like substrate from mushrooms). During the course of Klarenbeek’s work, he 3-D printed chair structures from a combination of mycelium, wood chips and straw. His goal was to use locally available resources to create durable and functional objects.

Later, he partnered with Maartje Dros, another Dutch designer, to develop biodegradable plastics from algae that they now use to 3D print objects. Together, they have researched algae bioplastics in partnership with Wageningen University and Avans Biobased Lab in the Netherlands, among other institutions. Klarenbeek and Dros have established an Algae Lab at the Atelier Luma’s production workshop in Arles, France where their technology is further developed. Today, the duo (Klarenbeek and Dros) run a studio in the Netherlands that focuses on the production and processing of macroalgae, and its possibilities for a local production cycle, from seaweed farming to end product.

After 8 years performing bioplastics research during my PhD at Stanford, I know firsthand the challenges that come with trying to print these plastic types. Most bioplastics today cannot be 3-D printed because they are either not flexible enough, or they melt away during the printing process. This achievement by Klarenbeek and Dros is simply revolutionary.

So What Exactly is Algae?

Before going any further, let’s dive into the world of Algae. Algae is a term used to define a diverse group of organisms that obtain their energy and food from sunlight, carbon dioxide and water. In other words, algae are photosynthetic.

Algae exists in three different forms and can take on different shapes or sizes. First, there are single-celled and microscopic (invisible) algae as big as 2 micrometers (think of the pore size of a surgical mask). Then there are single-celled and macroscopic (visible) – these are much bigger. Algae can also take on a leafy form like seaweeds and kelp. These “leafy” algae have multiple-cells, and grow as long as 60 meters or more.

While algae are mostly found in all kinds of aquatic habitats — either free-floating or sitting at the bottom of saltwater or freshwater — algae can also live in some unexpected places. Algae grows on mud, stones, tree trunks, as well as other plants and animals. In fact, they are so good at forming collaborative symbiotic relationships that you can think of them as omnipresent in nature.

How Are Algae Bioplastics Made?

While the exact process and formulation for the algae plastics made by Klarenbeek and Dros remains a secret, the steps they take to get from algae to 3-D printed plastic can be broken down into 4 “pretty straightforward” stages:

- The Selection & Harvest Process

First they identify the right types of algae and usually harvest them from aquatic habitats like ponds. They have currently used algae such as seaweed and spirulina in their processes.

- The Cultivation Process

Next, Klarenbeek and Dros grow a selection of algae in saltwater to obtain starch and fibermass for further production. Based on my experience working with microorganisms (bacteria to be more specific), this stage of the process is extremely crucial. Cultivating and maintaining organisms could make or break the process flow. However, this does not seem to be the case with algae. Algae grows very fast with a minimum nutrient requirement, and they are much more “low maintenance” compared to bacteria. Klarenbeek and Dros have also experimented using algae as a natural pigment and plasticizer.

- The 3-D Printing Preparation

Once the algae has grown appreciably, the duo (Klarenbeek and Dros) dry the wet biomass and grind it up to obtain a powder. The powdered algae is mixed with another bioplastic (potentially an algae plasticizer) which acts as a binder. This mixture is fed into a machine (called an extruder) that melts the mixture to form a continuous thread (called a filament) which looks like wool ready for knitting.

- The Biopolymer Printing Process

The algae thread is fed into a 3-D printer which the duo uses to build a variety of objects. 3-D printing is simply a process of manufacturing a desired product from a digital image with specific dimensions.

These bioplastics can be altered to suit different applications. And like I mentioned previously, these algae bioplastics by Klarenbeek and Dros are excellent for 3-D printing applications.

Why is Algae Important To The Planet?

Algae generates more than 50 percent of the Earth’s oxygen, making them one of the most important organisms on the planet today. Frankly, earth would not be able to support human existence at its current capacity without the help of these “gooey” organisms. Algae can remove tons of CO2 from the atmosphere, which makes them major players in climate change mitigation. More so, algae grows very quickly. They accumulate high levels of oils, carbohydrates, proteins and vital vitamins making them literally a “super” do-it-all organism.

What Can Algae Plastics Be Used To Make?

Klarenbeek and Dros’ algae products can be used to make every kind of plastic material. From furniture to dishware to detergent containers to plastic bottles. You name it! Ultimately, Klarenbeek and Dros want local restaurants and catering events to use tableware made from their 3-D printed algae plastics.

Fun fact! I recently watched a science-fiction show called The 100. The whole idea in this post-apocalyptic drama series is to demonstrate how humans can survive under devastating conditions. Guess what? The most reliable food source they turned to was Algae. For 6 years on a spaceship, Monty’s Algae farm fed the entire group. Pretty fascinating how even sci-fi creators can see into the future too.

A Decentralized System of Delivery

Eventually, Klarenbeek and Dros desire to build a decentralized network of 3-D printing hubs they plan to call the 3D Bakery. They want people to grow their own raw materials locally and create products that suit their specific needs. Just like the hot coffee in a kelp-cup. How cool is that!

How Ready is This Algae Plastic Technology?

Klarenbeek and Dros have no ambition to become a large centralized organization. However, they envision the 3D Bakery will be fully operational before 2030.

With that said, it is important to highlight the challenges facing the bioplastics industry today. The biggest being the cost of production. Polyethylene (PET) — made from crude oil and used to make all sorts of things like plastic bottles, milk jugs, detergent containers — is the cheapest plastic to produce to date. With the sharp decline in oil prices, the use of fossil-fuels remains the cheapest pathway to plastic production. Large corporations are more interested in scalable, easy to produce processes while current plastic manufacturing infrastructure is still very archaic and unable to adapt to new material inputs. The competition for bioplastic producers is steep. These sustainable alternatives need to evolve at a much faster pace to outcompete what is currently status-quo.

Nonetheless, I am optimistic about Klarenbeek and Dros’ algae plastic technology. It is a major advancement in biodegradable plastic production and should attract a lot of interest from corporations looking to curb plastic usage. As I mentioned in my previous article, plastic pollution is a huge threat to the environment and human-health, and this problem cannot be overlooked.

Now. If you are like me, then at this point you are asking yourself, “Could algae really be that thing that saves us?” Well…The jury is still out.

Until next time!

One thing I want to touch upon is that fat reduction plan fast can be achieved by the suitable diet and exercise. People’s size not just affects the look, but also the complete quality of life. Self-esteem, major depression, health risks, plus physical capabilities are influenced in putting on weight. It is possible to just make everything right but still gain. In such a circumstance, a condition may be the culprit. While too much food rather than enough workout are usually responsible, common health concerns and traditionally used prescriptions can certainly greatly amplify size. Thx for your post in this article.

Снимали 90 квадратов производственных площадей.У нас вы найдете большой ассортимент товаров данного производителя.

[Link deleted]

[Link deleted]

[Link deleted]

Именно для этого им необходимо качественное надежное веселое игровое оборудование для детских площадок.Любителям вполне достаточно уделять 30 минут на шаговом или любом другом типе механизма и со временем эффект будет заметен.

<a href=[Link deleted]москва

[Link deleted]

<a href=[Link deleted]

<a href=[Link deleted]the complex world of chronometers

Understanding COSC Accreditation and Its Importance in Watchmaking

COSC Validation and its Demanding Criteria

COSC, or the Official Swiss Chronometer Testing Agency, is the official Swiss testing agency that verifies the accuracy and accuracy of wristwatches. COSC validation is a sign of superior craftsmanship and reliability in timekeeping. Not all timepiece brands seek COSC validation, such as Hublot, which instead adheres to its own demanding standards with movements like the UNICO, achieving equivalent accuracy.

The Art of Precision Timekeeping

The central mechanism of a mechanical timepiece involves the spring, which provides power as it loosens. This system, however, can be vulnerable to external factors that may influence its precision. COSC-validated movements undergo rigorous testing—over 15 days in various conditions (five positions, three temperatures)—to ensure their resilience and reliability. The tests evaluate:

Average daily rate precision between -4 and +6 seconds.

Mean variation, maximum variation levels, and effects of temperature variations.

Why COSC Accreditation Is Important

For watch fans and collectors, a COSC-accredited timepiece isn’t just a piece of technology but a testament to enduring quality and accuracy. It signifies a watch that:

Offers excellent dependability and precision.

Ensures confidence of superiority across the whole design of the watch.

Is apt to retain its worth more effectively, making it a smart investment.

Well-known Chronometer Brands

Several renowned manufacturers prioritize COSC accreditation for their timepieces, including Rolex, Omega, Breitling, and Longines, among others. Longines, for instance, offers collections like the Record and Spirit, which showcase COSC-accredited movements equipped with advanced materials like silicone balance suspensions to improve durability and performance.

Historical Context and the Evolution of Timepieces

The idea of the chronometer originates back to the requirement for exact chronometry for navigational at sea, emphasized by John Harrison’s work in the 18th century. Since the official establishment of Controle Officiel Suisse des Chronometres in 1973, the accreditation has become a yardstick for assessing the precision of high-end timepieces, sustaining a legacy of superiority in watchmaking.

Conclusion

Owning a COSC-accredited timepiece is more than an visual selection; it’s a dedication to excellence and precision. For those appreciating accuracy above all, the COSC certification provides peace of mind, guaranteeing that each validated timepiece will function reliably under various conditions. Whether for personal contentment or as an investment decision, COSC-accredited watches stand out in the world of horology, carrying on a tradition of precise timekeeping.

Understanding COSC Accreditation and Its Importance in Watchmaking

COSC Certification and its Stringent Standards

COSC, or the Official Swiss Chronometer Testing Agency, is the official Switzerland testing agency that certifies the accuracy and accuracy of wristwatches. COSC validation is a sign of superior craftsmanship and trustworthiness in timekeeping. Not all watch brands follow COSC validation, such as Hublot, which instead sticks to its proprietary stringent standards with movements like the UNICO calibre, attaining equivalent accuracy.

The Art of Exact Chronometry

The core system of a mechanized watch involves the mainspring, which supplies power as it unwinds. This mechanism, however, can be prone to external elements that may affect its precision. COSC-accredited mechanisms undergo rigorous testing—over fifteen days in various conditions (five positions, three temperatures)—to ensure their resilience and dependability. The tests measure:

Average daily rate precision between -4 and +6 secs.

Mean variation, peak variation levels, and effects of thermal changes.

Why COSC Validation Is Important

For watch aficionados and connoisseurs, a COSC-accredited watch isn’t just a item of technology but a testament to enduring quality and precision. It represents a watch that:

Provides excellent dependability and accuracy.

Provides confidence of superiority across the whole construction of the timepiece.

Is probable to maintain its value more effectively, making it a smart investment.

Popular Timepiece Manufacturers

Several well-known manufacturers prioritize COSC certification for their timepieces, including Rolex, Omega, Breitling, and Longines, among others. Longines, for instance, offers collections like the Archive and Spirit, which highlight COSC-accredited movements equipped with innovative materials like silicone balance springs to enhance resilience and performance.

Historic Background and the Evolution of Timepieces

The notion of the timepiece originates back to the need for exact timekeeping for navigational at sea, highlighted by John Harrison’s work in the 18th cent. Since the formal foundation of COSC in 1973, the certification has become a benchmark for judging the precision of high-end watches, sustaining a legacy of superiority in watchmaking.

Conclusion

Owning a COSC-validated timepiece is more than an visual selection; it’s a dedication to excellence and accuracy. For those appreciating precision above all, the COSC certification provides tranquility of thoughts, guaranteeing that each validated timepiece will operate dependably under various circumstances. Whether for personal contentment or as an investment decision, COSC-validated watches stand out in the world of horology, bearing on a legacy of precise chronometry.

로드스탁과의 레버리지 스탁: 투자의 새로운 지평

로드스탁을 통해 제공하는 레버리지 스탁은 증권 투자의 한 방식으로, 상당한 수익률을 목적으로 하는 투자자들에게 매혹적인 옵션입니다. 레버리지를 사용하는 이 방법은 투자자들이 자신의 자금을 초과하는 투자금을 투입할 수 있도록 함으로써, 증권 장에서 더욱 큰 영향력을 가질 수 있는 기회를 공급합니다.

레버리지 스탁의 기본 원칙

레버리지 스탁은 일반적으로 자본을 차입하여 운용하는 방법입니다. 예시를 들어, 100만 원의 자본으로 1,000만 원 상당의 증권을 취득할 수 있는데, 이는 투자하는 사람이 기본 투자 금액보다 훨씬 더욱 많은 주식을 사들여, 증권 가격이 올라갈 경우 해당하는 더 큰 수익을 획득할 수 있게 해줍니다. 그러나, 주식 값이 떨어질 경우에는 그 손해 또한 크게 될 수 있으므로, 레버리지 사용을 사용할 때는 조심해야 합니다.

투자 계획과 레버리지 사용

레버리지 사용은 특히 성장 가능성이 상당한 사업체에 투입할 때 유용합니다. 이러한 사업체에 높은 비중으로 투입하면, 성공적일 경우 상당한 수입을 얻을 수 있지만, 그 반대의 경우 큰 리스크도 감수해야. 그러므로, 투자하는 사람은 자신의 위험 관리 능력과 상장 분석을 통해 통해, 어느 기업에 얼마만큼의 자본을 투자할지 결정해야 합니다.

레버리지 사용의 장점과 위험 요소

레버리지 방식의 스탁은 큰 수익을 약속하지만, 그만큼 높은 위험성 수반합니다. 주식 장의 변동은 추정이 힘들기 때문에, 레버리지 사용을 이용할 때는 늘 시장 추세를 정밀하게 주시하고, 손실을 최소로 줄일 수 있는 계획을 구성해야 합니다.

최종적으로: 신중한 선택이 요구됩니다

로드스탁을 통해 제공하는 레버리지 스탁은 막강한 투자 수단이며, 잘 이용하면 상당한 이익을 제공할 수 있습니다. 그러나 큰 리스크도 고려해야 하며, 투자 선택은 필요한 정보와 세심한 생각 후에 진행되어야 합니다. 투자하는 사람의 금융 상황, 리스크 감수 능력, 그리고 장터 상황을 반영한 조화로운 투자 전략이 중요합니다.